Infrastructure

OUR STRUCTURE

With years of experience in manufacturing high quality fabrics and garments, we are pioneers in the field of manufacturing and exporting knitted apparels. We are known for our trendy and designer to well-known and are in line with latest national and international fashion trends.

We possess a fleet of highly dedicated and adept professionals who have a constant urge to provide garments of latest designs and trends. Our teams of expert quality analyzers inspect every apparel during the procurement process to ensure zero defect products. We are always at our feet to provide the products on time thus ensuring reliable supply and prompt delivery.

Quality being our focus is followed unconditionally. Our quality checks begin from the first stage of raw material procurement by our quality inspectors who ensure compliance to defined parameters. Raw material from trusted vendors, help us assure quality of the products delivered. Stringent quality assessment on various parameters like quality of the fabric, tear strength, stitch, color fastness’s, shrinkage possibilities etc., are carried out by us. The functionality and efficiency checks of the machines, installed in our production unit, are also conducted on timely basis. Creating new standards of quality in manufacturing knit wears is the hallmark of steady growth in the industry.

INFRASTRUCTURE

Summer Breeze Garments has an excellent garment production unit which is well designed with ample workspace, adequate natural lighting and extensive ventilations. Summer Breeze Garments in-house garment production facility is well equipped with latest state of the art machinery in fabric cutting, fusing, sewing, finishing & packing, resulting in better quality & higher efficiency in productivity. Every style is time & method engineered to improve productivity & achieve delivery deadlines.

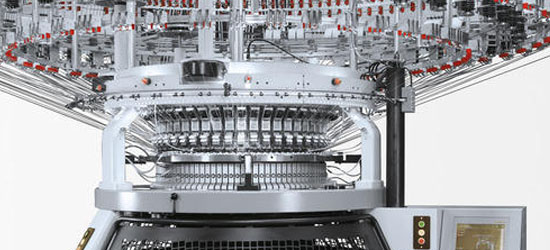

KNITTING

Summer Breeze Garments has associate Knitting machines. We can do all types of knitted fabrics as per our customer specification and style, which includes Single Jersey, Interlock, French Terry and all types of Ribs, Jackquard designs,Loop Knit, Fleece, Blended, Auto stripes.

DYEING

Summer Breeze Garments has associate Dyeing machines. These Machines are totally Automatic and computer controlled

PRINTING

Our proficiency lies in making a wide range of printing patterns possible. Towards this, we have table & machine printing facility that enable a diverse variety of prints.

Pigment print, Plastisol print, Discharge print, Glitter Print, Flock print, Foam print, Digital Transfer print, High Density print , etc..,

EMBROIDERY

The highly advanced Tajima machine with 20 heads makes it easy for us to craft the finest embroidery designs.

The embroidery division is equipped with the latest machines from TAJIMA-(Japan Make).These automated embroidery machines elegantly handle any design with Punching ,Designing & Applique Cutting.

CUTTING

Summer Breeze Garments has associate Cutting machines Fabric cutting that ensures the desired styles has been perfected with the use of computerized Lectra CAD markers.

Lay cutting machines with automatic spreader that are highly advanced in our production unit. To avoid angle variations in shape, we use effective band knife cutting machines.

GARMENTING

The garments are manufactured in most sophisticated machines using the latest state of the art technology in our INHOUSED PRODUCTION UNIT. Our wide range of machineries include. Our Production is the key for success which keeps us growing in this competitive industry. Our production unit is supported by 100 sewing machines.

PACKING

They are packed neatly in the designated packs and placed inside the carton or hanger racks for dispatch.